|

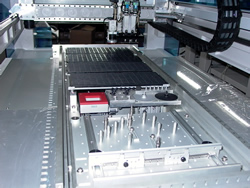

Fully Automatic Pick & Place Machine |

|

|

Model:BS387V1 / BS387V2 |

|

|

|

|

|

|

|

· High Accuracy, High Flexibility for

0201(0.6mmX0.3mm)SOIC,PLCC,BGA, |

|

· Smart Feeder System -Automatic feeder

position checking -Automatic component counting -Production data Trace ability |

|

· Suitable for small volume production |

|

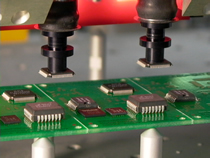

· Vision on the Fly Alignment System |

|

· Bottom Vision Alignment System for

fine pitch QFP and BGA |

|

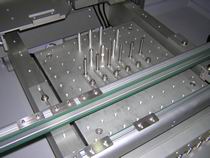

· Install 152pcs Smart Feeder (8/12mm)

and 4pcs IC-Tray simultaneously |

|

· Dispenser System |

|

· Vision Inspection for before or after

production |

|

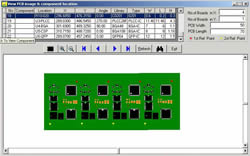

· Universal CAD Conversion |

|

· Windows 2000 Software |

|

· PCB Size up to 900mmX400mm |

|

· Non-Contact Linear Encoder System |

|

|

|

Product

Information |

|

Strong & Rigid

Structure |

|

|

Non-Contact Linear Encoder

System |

|

|

Vision on the Fly

Alignment System |

|

|

Dispenser System |

|

|

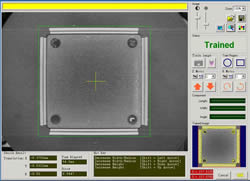

Flexibility Fiducial

Mark System |

|||

|

Circular solder pad |

square solder pad |

plate-through hole |

|

|

|

|

|

|

|

Vision Alignment

System |

||

|

BGA IC |

QFP IC |

|

|

|

|

|

|

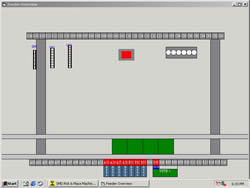

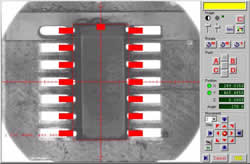

Programme can view |

||

|

PCB Overlay |

Feeder Overview |

|

|

|

|

|

|

Smart Feeder Half step (2mm advance) smart feeder also available for 0201/0402 component. |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Universal IC Tube

Feeder KFTB-2 (10pcs of 8mm tube) |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Quick Change Feeder

Rack FR-32 can adapt 32pcs of 8/12mm tape feeder

or 40pcs of 8mm tube feeder

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Optional Conveyor

System |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Buffering Nozzle |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Remote Service Kit |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Vision Inspection |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Universal CAD

Conversion |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Bilgiç Danışmanlık Tel: +90 216 471 7755 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||